ACC has been continuously striving to improve energy and environmental performance supported by a strong top management commitment.

Our environmental policy is designed to contribute to building a better world. We operate our facilities in accordance with local laws, standards and regulations; applying state-of-the-art environmental management systems.

At ACC, we are always keen to minimize the use of non-renewable resources whenever possible. We also work on limiting the hazardous outcomes and other wastes of our operations. This could be achieved by using substitute raw materials and alternative fuels as well as disposing of wastes using safe and environment-friendly methods. It is our duty to conduct environmental audits for all facilities periodically.

We have implemented cutting-edge technologies and adopted organizational structures to facilitate the usage of many types of alternative fuels from scratch since 2013, achieving high substitution rates of alternative fuels over standard fuels. We are pioneering in the use of alternative energy in the Egyptian cement industry as the first cement company in Egypt to establish a solar power station inside its plant. In 2019, ACC won the first prize in this year’s competition “1st Alternative Fuel Award 2019” from MVW – LECHTENBERG & PARTNER.

ACC Environmental Policy

Sustainable Development is the foundation of ACC’s environmental policy to contribute to building a better, greener world.

Environmental commitment aims at doing less harm by mitigating negative operational impacts and saving energy by operating our facilities in compliance with local laws, standards, and regulations. We apply state-of-the-art environmentally friendly technologies to reduce CO2 quantities and are committed to the Ministry of Environmental Affairs regulations and controls including installation of measuring instruments on all our chimneys connected to the National Environmental Control Network which enables the on line monitoring of the emissions to comply with environmental law limits.

We conduct environmental audits for all facilities on a routine schedule to work environment and ambient air. We also continuously develop rehabilitation plans for all quarry sites that takes account of the needs and expectations of our stakeholders and, where feasible, fosters wildlife habitat creation and contributes to the conservation of endangered species.

ACC implements sustainability and product stewardship practices in the design, manufacturing, distribution, and application of our products. This enhances their contribution to sustainable construction, minimizes their impact on human health and the environment, and reduces the waste produced by operations and uses the waste in the alternative fuel system, in addition to reusing our own byproducts and these of other industries and promoting recycling.

ACC seeks to maximize the use of renewable resources. This could be achieved by using alternative raw materials and alternative fuels.

ACC promotes environmentally responsible attitudes and behaviors by continuously managing and integrating the environmental management system into our business processes with clear responsibilities. We encourage suppliers, customers and other business associates to adopt similar practices. We are aware of the need to work closely with our contractors and suppliers, and encourage all stakeholders to communicate any concerns they may have regarding environmental issues.

ACC is committed to providing training and applying industry best practices to support the understanding of our responsibilities to operate in an environmentally responsible manner and to achieve a high standard of environmental commitment.

Biodiversity policy

Scope & Responsibilities

Our ‘Biodiversity Statement’ applies to all ACC’ operations, including all our business units and subsidiaries. We will work with our internal and external stakeholders to ensure all parties are aware of our commitments and ambitions to meaningfully reduce impacts, restore and protect ecosystems and their biodiversity.

Our Commitment Includes:

Sustainable Practices: We will integrate sustainable practices into our business operations, ensuring minimal impact on ecosystems and promoting the responsible use of natural resources.

Biodiversity Assessment: We will conduct regular assessments to understand our impact on local biodiversity, making informed decisions to mitigate any adverse effects.

Collaboration: We will collaborate with local communities, non-profits, and other stakeholders to strengthen biodiversity conservation efforts and promote environmental stewardship.

Education and Awareness: We will promote awareness of biodiversity's importance among our employees, stakeholders, and customers, fostering a collective sense of responsibility and action.

By embodying these commitments, ACC seeks to contribute positively to the preservation of our planet's biodiversity for future generations while ensuring the long-term sustainability of our business.

ACC is a reliable clinker and cement supplier, committed to exceeding our customers’ expectations through an efficient multi-skilled team focused on our core business and supported by the latest technologies.

We adopt and implement quality and safety management systems that comply with international best practices and standards: ISO 9001:2015 and ISO 45001:2018.

Our quality, and occupational health and safety is based on seven principles:

1. Provide a healthy and safe work environment for employees, visitors and contractors.

2. Comply with the applicable occupational health and safety legal obligations and customer requirements.

3. Detect, control, eliminate, or mitigate occupational health and safety risks associated with the company’s operations and activities.

4. Set and continuously review the company's objectives and goals in order to plan improvements that support the sustainability of the organization.

5. Measure and monitor our customers’ needs fulfillment with the aim of reaching maximum customer satisfaction.

6. Select qualified, multi-skilled, and professional staff and support their continuous performance.

7. Continuously improve and upgrade the performance of the quality and safety management systems in order to meet the highest standards.

All required information about product risks and safety are provided to the buyer as attachment to the purchase order and the essential safety information for the product user are available on our cement bags.

ACC factory consists of two identical and fully equipped clinker lines with an annual production capacity of 2.1 million tons each. Our state-of-the-art equipment and technology supports a streamlined process and adaptability to local conditions. The plant machinery is of the most advanced proven design, supplied by world’s leading equipment manufacturers.

ACC’s limestone quarry is located 2.8 KM from the plant site. Nearby, the raw material crusher receives the limestone together with the outsourced clay. After crushing, the raw mix is transported via belt conveyor to the storage inside the factory. The limestone-clay mixture is automatically controlled by a gamma ray cross belt analyzer.

Other materials needed for clinker and cement production, in lesser quantities, are directly delivered to the plant by truck.

Prior to the pyro-process, the raw mix, together with minor additions of sand and iron ore, is ground into vertical mills (2 ATOX 45) capable of grinding up to 500 t/h at the required fineness.

The five stage ILC Preheater/Kiln/Cooler systems, which are the core of the pyro-process, are the biggest capacity ever built in Egypt to date, designed for 6000 t/day each line. It can produce up to 6700 t/d steadily and comfortably. The clinker freshly produced is stored in 35,000 ton clinker silos. Each clinker line is equipped with two horizontal ball mills capable of grinding 200 t/h for a total installed capacity of 800 t/h cement production. To store the different types of cement, four silos with a capacity of 15,000 tons each are available. All silos have truck loaders underneath and feeding systems to the packing plants.

Both packing plants consist of 3 packing machines of 120 t/h each and 1 palletizer with a capacity of 210 t/h. Each packer can either feed the palletizer, or two manual truck loading points, which allows them to run continuously 24 hours per day. This way, 720 t/h can be loaded at any time but also, in peak times, forklifts can load more cement from two storage areas with a capacity of 2,000 tons each, where freshly produced palletized cement is stored.

All processes are monitored and controlled by PLC centralized in the Control Room, and the quality of each production step is controlled by fully equipped laboratory and personnel 24 hours per day 7 days per week.

Arabian Cement has established and applies a quality, safety, environmental and energy management systems, with the aim of enhancing overall business position and performance, reaching the highest level of stakeholders’ satisfaction, and continuously improving the measures of internal control.

The aforementioned management systems have been certified individually as stand-alone systems and are being audited by well-known certification bodies which are internationally accredited and have the know-how to certify a wide range of internationally recognized management systems in various sectors and industries.

The certifications were granted, after proof has been furnished that the requirements according to the relevant international standards are fulfilled.

In line with our vision and mission, we adopted and applied an integrated management system combining quality, occupational health & safety, environmental and energy management systems, that complies with the requirements of the international standards of ISO 9001:2015 – ISO 45001:2018 – ISO 14001:2015 – ISO 50001:2018 – CE 197-1:2011 (Conformité Européenne) – NF 197-1:2012 (Normes Françaises) respectively.

Beyond certification, internal and external audits are performed, along with frequent management reviews to ensure the continuing suitability, adequacy and effectiveness of the implemented management systems. The results and outcomes are reported directly to the top management to take prompt decisions and actions when needed.

Arabian Cement is always striving for continuous improvement, and dedicated to maintain world-class management systems.

| Year | Management System | International Standard | Status |

|---|---|---|---|

| 2010 | Quality | ISO 9001:2008 | Certified |

| 2011 | Quality | ISO 9001:2008 | Certified |

| 2013 | Occupational Health & Safety | BS OHSAS 18001:2007 | Certified |

| 2013 | Environmental | ISO 14001:2004 | Certified |

| 2016 | Energy | ISO 50001:2011 | Certified |

| 2016 | Quality | ISO 9001:2015 | Certified |

| 2016 | Environmental | ISO 14001:2015 | Certified |

| 2017 | Integrated Management System Quality Management System Occupational Health and Safety Assessment Series Environmental Management System Energy Management Systems |

ISO 9001:2015 OHSAS 18001:2007 ISO 14001:2015 ISO 50001:2011 |

Certified |

| 2018 | Integrated Management System Quality Management System Occupational Health and Safety (OH&S) Management System Environmental Management System Energy Management Systems Products Conforming to European Standards Products Conforming to Standards of France |

ISO 9001:2015 ISO 45001:2018 ISO 14001:2015 ISO 50001:2018 CE 197-1:2011 (Conformité Européenne) NF 197-1:2012 (Normes Françaises) |

Certified |

| 2019 | Integrated Management System Quality Management System Occupational Health and Safety (OH&S) Management System Environmental Management System Energy Management Systems Products Conforming to European Standards Products Conforming to Standards of France |

ISO 9001:2015 ISO 45001:2018 ISO 14001:2015 ISO 50001:2018 CE 197-1:2011 (Conformité Européenne) NF 197-1:2012 (Normes Françaises) |

Certified |

| 2020 | Integrated Management System Quality Management System Occupational Health and Safety (OH&S) Management System Environmental Management System Energy Management Systems Products Conforming to European Standards Products Conforming to Standards of France |

ISO 9001:2015 ISO 45001:2018 ISO 14001:2015 ISO 50001:2018 CE 197-1:2011 (Conformité Européenne) NF 197-1:2012 (Normes Françaises) |

Certified |

| 2021 | Integrated Management System Quality Management System Occupational Health and Safety (OH&S) Management System Environmental Management System Energy Management Systems Products Conforming to European Standards Products Conforming to Standards of France |

ISO 9001:2015 ISO 45001:2018 ISO 14001:2015 ISO 50001:2018 CE 197-1:2011 (Conformité Européenne) NF 197-1:2012 (Normes Françaises) |

Certified |

| 2022 | Integrated Management System Quality Management System Occupational Health and Safety (OH&S) Management System Environmental Management System Energy Management Systems Products Conforming to European Standards Products Conforming to Standards of France |

ISO 9001:2015 ISO 45001:2018 ISO 14001:2015 ISO 50001:2018 CE 197-1:2011 (Conformité Européenne) NF 197-1:2012 (Normes Françaises) |

Certified |

(1) In 2011, the certification scope of the QMS was extended to include the production and sales cement.

ACC is pioneering the industry with bold, efficient, reliable and sustainable advancements. We are among the first cement companies to implement a groundbreaking approach to alternative fuel consumption in Egypt, having invested millions of dollars to shift to the use of alternative fuel and more environmentally-friendly resources, including renewable energy.

In 2014, the Egyptian government announced it would begin phasing out energy subsidies. This has driven us to put even additional efforts in improving our energy performance. ACC partnered with UNIDO through the industrial energy efficiency program to support the implementation of an EnMS in compliance with ISO 50001.

ACC participated in an energy bench marking study for the Egyptian cement sector where we were evaluated as the top performer within the sampled organizations. This has further motivated the top management to continue our efforts towards more sustainable production.

To support this approach, ACC established an EnMS that institutionalized a systematic approach to managing, monitoring, and improving energy performance. These efforts were recognized through the certification by TUV (Nord) based on third-party auditing.

In addition, ACC won an Award of Excellence in EnMS from the Clean Energy Ministerial (CEM) in 2017, a high-level global forum that promotes policies and programs to advance clean energy. this award recognizes the top ISO 50001-certified organizations that demonstrate exemplary leadership in energy management and share insights that can help accelerate use of ISO 50001 and its economic and environmental benefits worldwide.

ACC was also awarded “Middle East Region Energy Project Award of the year“ in 2019 from the Association of Energy Engineers (AEE). In 2022, ACC was awarded the Appreciation Award in the yearly competition “Arab Energy Efficiency Day” organized by the Arab League, for the company’s distinctive role in energy efficiency.

ACC uses the most updated technologies in the operation of the plant and we are the first cement plant in Egypt to use solar energy which also provides financial benefits through cost savings as well as environmental benefits through reducing carbon footprint.

In the context of the Egyptian environmental regulations, the compliance audit conducted by the Egyptian Pollution Abatement Project (EPAP II) shows that Arabian Cement Company is complying with the applicable regulations in terms of air emissions, wastewater, and solid and hazardous waste management practices.

ACC aims to support the reduction of greenhouse gases emissions by partial replacement of fossil fuels with alternate fuels (rejects from municipal solid wastes, dried sewage sludge from water treatment plants, industrial wastes, agricultural wastes, and licensed to burn different kind of hazardous wastes.

Apart from a willingness to play our part in contributing to global greenhouse gas emission reductions, another key driver for ACC is energy security. Although ACC is equipped to use natural gas, diesel oil or even solid fuels (coal and/or petcoke), with increasing energy costs and concerns over energy availability in the future, ACC is driving energy efficiency in our production processes and to substitute the valuable fossil fuels with waste-derived fuels wherever possible and feasible.

By the end of 2013, ACC started using alternative fuels and was targeting to achieve 30% of its total required energy. Such approach would greatly contribute to the sustainable development in Egypt.

ACC is using a variety of methods to reach our alternative fuel target by reducing our dependence on fossil fuels through partial replacement by alternative fuel, maximizing both energy efficiency and total thermal substitutions rate, as well as supporting the ecological system by reduction CO2 emissions. One method is the installation of a HOTDISC system in line 1, an effective combustion device that can burn all kinds of solid wastes thereby reducing the investment and operational cost of pre-treatment of wastes. ACC’s use of the HOTDISC system is the first time such technology has been used for alternative fuels in Egypt, and it is considered the 9th installation worldwide, and 1st installation of FLS 3rd generation with a design capacity of up to 30 tph.

ACC has registered its alternative fuel activities as a Clean Development Mechanism (CDM as defined in the Kyoto Protocol) resulting in an average annual emission reduction of approximately 100,000 tons of CO2/yr over 10 years.

In 2016, Evolve Investments and Project Management was founded as a subsidiary of Arabian Cement Company. It specializes in build-own-operate waste treatment plants and providing organic and alternative fuels to energy-intensive industries. Evolve provides alternative fuels to ACC and other local companies, enhancing their operations and positively impacting the environment. As part of ACC’s commitment to reduce CO2 emissions, the company is using environmentally friendly carbon neutral sources of fuel provided by Evolve.

As a key player in the waste management industry, Evolve is a trusted partner for the safe disposal of waste. Through strong and long-lasting business relationships with waste producers in Egypt, Evolve secures varied waste sources ranging from municipal solid waste (MSW), industrial waste and agricultural waste.

Through Evolve, ACC aims to offer integrated alternative fuel solutions to other industries, extending and enhancing the beneficial effect that the organized treatment and disposal waste will have on Egypt.

In addition, Evolve is helping improve the community by collecting large quantities of industrial and municipal waste from other companies and municipalities that otherwise would have ended up polluting Egypt’s land and rivers.

Evolve also offers consultancy services to local authorities to support the development of waste management systems and to encourage more industry players to take advantage of the many opportunities found in this sector.

ACC is committed to promote the responsible sourcing as an integral part of running responsible business.

Our Aim Element of responsible sourcing are:

• Transparent Supplier Requirements

Ensuring that all our supplier operate responsibly according to agreed standards as ACC has a commitment to not sourcing materials from or conducting business activities in areas that are environmentally or culturally sensitive.

• World Heritage Sites (designated by UNESCO)

• Key Biodiversity Areas (KBAs) or Protected Areas

• National Parks or other legally protected sites

• Respecting Indigenous and Local Communities: Avoiding business activities that might negatively affect Indigenous lands or culturally important areas, ensuring that communities' rights and land are protected.

• No sourcing from protected areas: This could involve ensuring that all raw materials do not come from protected forests, wildlife reserves, or ecosystems that are crucial to biodiversity.

• High Conservation Value (HCV) Areas: A commitment to avoid areas identified as having significant environmental, cultural, or social value, often aligned with international frameworks such as the Forest Stewardship Council (FSC)

• Supplier Risk Assessment

Purchasing from qualified supplier and carrying out audits of suppliers based on potential risk.

• Cooperation for continuous development

Working together with our supplier and partners to improve standard of practice.

ACC is committed to adopting sustainable practices that reduce the environmental impact of production processes.

As part of this commitment, we are increasingly incorporating secondary raw materials into cement production. These materials, derived from waste and by-products of other industries, help reduce the demand for virgin natural resources and lower GHG emissions.

ACC uses and aims to use many sources of Secondary raw materials such as pozzolanic material, air cooled slag, as well as recycled construction and demolition waste depending on raw material availability by substituting these materials for primary raw materials like clinker, limestone and clay, the cement industry can:

• Reduce raw material extraction: Using secondary materials lessens the environmental strain caused by quarrying activities.

• Lower CO2 emissions: Many secondary raw materials contribute to lower energy consumption during the clinker and cement production process, reducing carbon emissions.

• Support the circular economy: Incorporating waste from other industries into cement production helps reduce landfill disposal and promotes resource reuse.

ACC considers itself part and parcel of the Egyptian society, and we therefore realize how important it is to operate, collaborate and participate in cultural and sporting activities that help to promote personal skills, creativity and self-improvement. Our main goal is to promote activities with significant social impact: training in cooperation with universities, libraries, cultural centres, sponsorship of sports teams, etc.

Competition Supporting Startups in Suez

Arabian Cement Company (ACC) announced on October 28th the names of the final winners of “Khaleeha Suessi” program. In the presence of Mr. Al Arabi Al Serwi, Governor of Suez, Jose Maria Magrina, ACC Chief Executive Officer and Loay El-Shawarby, Chairperson of Nahdet El Mahrousa revealed the names of the six projects that will be offered seed funding as well as one-year incubation at Nahdet El Mahrousa. The announcement was made in Suez governorate, with senior officials from ACC attending.

“Khaleeha Suessi” was launched in June 2015 to promote positive social impact and employment opportunities by providing entrepreneurs with the tools needed to successfully establish their own social startups. The winning projects vary between environmental friendly industrial/agricultural ventures, cultural/social ventures and educational ventures. To qualify for the incubation phase, there were several criteria that the winning projects had to meet. These criteria included offering an innovative business idea that has the potential to become scalable and sustainable, and have social impact in Suez.

Over the period of four months, the program offered guidance for the applicants to support them in developing comprehensive proposals for their start-up. The final proposals of the applicants were considered by a panel of six experts including Eng. Fernas El Hakim, Governmental Affairs Director at ACC; Angy Samad, Marketing Manager at ACC; Dr. Ahmed Huzayyin, Co-founder of Cleantech Arabia; Dr. Ayman Ismail, Assistant Professor at the American University in Cairo; Tamer Mostafa, Chief Accountant at Nahdet El Mahrousa; and Jackie Kameel, Managing Director of Nahdet El Mahrousa.

At the end of the one-year incubation period, each project will be granted its allocated seed funding, as a means of supporting each team to successfully kickoff their business, using the skills and knowledge offered to them by “Khaleeha Suessi”.

Khaleeha Suessi Winning Projects

Suez Tire Recycling Factory

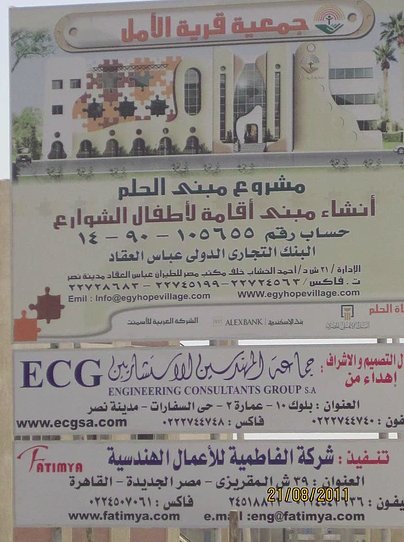

ACC has been supporting Hope Village Society to develop its “Dream Building” project since 2010. Among others, Hope Village Society initiatives include securing shelter to more than 300 orphans through its properties across Cairo, 10th of Ramadan and Alexandria. The Dream Building project aims at serving as an integrated shelter for all the Hope Village orphans. As such, ACC is collaborating with Hope Village by providing it with the cement needed to complete its project.

To date, over 40% of the project has been completed, and ACC will continue its support until the entire development is complete. ACC will also continue its support to Hope Village Society initiatives, aiming to deliver a better future for Egyptian children.